Why Manufacturing Execution Systems (MES) Matter

July 17, 2020 | Guest Author

By: Joe Baggett, Innovative Wood Process Solutions

Dwight Eisenhower once said, “Plans are worthless, but planning is everything.” America’s 34th president, who orchestrated the U.S. military victory in WWII, was celebrated for his mastery of logistics and organization, went on to explain what he meant by this apparent contradiction:

“The details of a plan which was designed years in advance are often incorrect, but the planning process demands the thorough exploration of options and contingencies. The knowledge gained during this probing is crucial to the selection of appropriate actions as future events unfold.”

This holds true in the manufacturing and fabrication of wood products and components. Manufacturing execution is the measurement of progress against a plan. The only plans that matter are those you actually do something about, and take seriously. The planning matters, but the execution and reaction to it matter even more.

Years ago, while working for a major casket manufacturer, we designed a line of caskets that used reclaimed lumber called core panel. The new manufacturing lines and room were well designed to make the core panels in a continuous line rather than batch, minimizing the number of hands touching it from machine to machine.

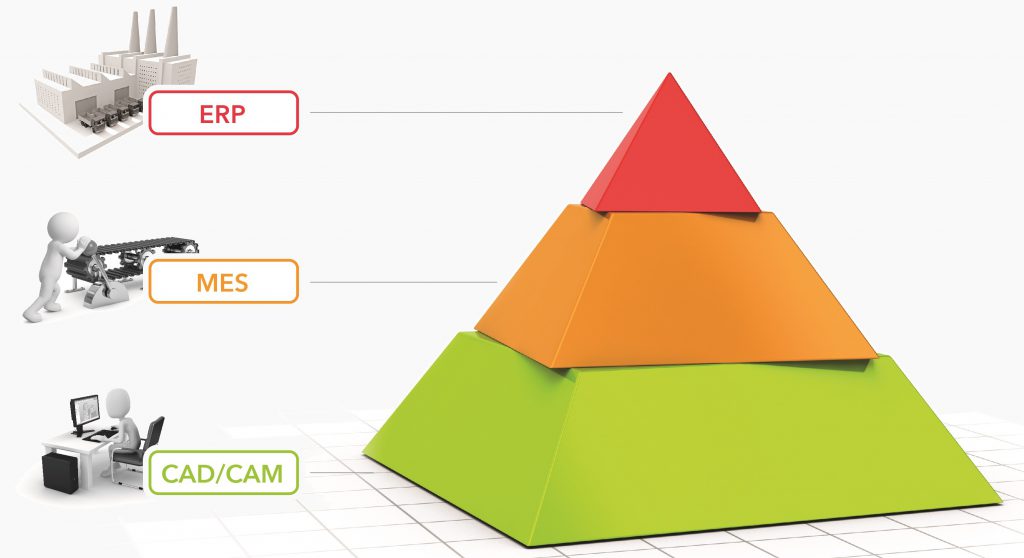

We quickly realized that something was missing. While good at providing a schedule, our ERP—the centralized Enterprise Resource Planning computer management system—was very limited in providing real-time feedback. This hour-by-hour execution of that schedule is the data that really mattered when we wanted to get projects out the door.

So, with some PLC technology and an old Allen Bradley program called Lab View, we developed a manufacturing execution system. It provided a schedule that was then downloaded for each shift, with an hourly goal by machine center, and delivered email notifications of things such as attainment, yield, rework, etc.

It was clunky, clumsy, and antiquated by today’s standards. But for its period and the technology available, it worked, and after launching it we received several industry awards. But during a management leadership meeting, we learned that many of the frontline production leaders were not using the data in real time. Why? Because the expectation for managers at the time didn’t lend itself to reacting hour by hour.

That should no longer be the case. These days manufacturing execution systems can be implemented by companies specializing in this area. Even so, when we do audits to assess how implementing an MES can bring value to a production operation, we usually find out that the information needed to make good decisions on an hourly basis isn’t available in the plant.

Ironically, we still find production leaders and engineers are consumed with trying to get the same data that today’s widely available MES software would provide automatically, and on a timely basis. Even more problematic from my assessments: managers continue to be limited in the more meaningful activity of using this data, and reacting to it in real time.

Getting started with manufacturing execution is the main point. Doing manufacturing execution well is one of the basic building blocks and part of the foundation of scalability of any manufacturing operation. Reliable hourly output against a plan is something that can be scaled. And scalability is one of the most important things for manufacturers, especially in the new world in which we find ourselves.

President at Innovative Wood Process Solutions Inc., Joe Baggett is a frequent presenter at the International Woodworking Fair Education Program. Contact him to receive his white paper on management execution systems.

Apply to Exhibit

Grow your business at the premier global woodworking trade show.

Show Hours & Location

International Woodworking Fair

Tuesday–Friday

August 6–9, 2024

Tuesday–Thursday

8:30 AM–5:00 PM*

Friday

8:30 AM–2:00 PM*

*Building A opens 7:30 AM Tue-Fri

Georgia World Congress Center

285 Andrew Young International Blvd

Atlanta, GA 30313