Swood Design Software by Eficad Integrates Hettich Hardware Library

June 9, 2021 | Bill Esler

Boston, MA—Hettich and Swood by Eficad—the CAD/CAM woodworking and furniture software suite integrated within Solidworks—have teamed up over recent months to develop a link between Hettich’s hardware products database and Swood’s libraries.

The tool lets Swood users access all Hettich products within their shared libraries. It also lets them update everything on demand, and it eliminates the need to set up a hardware library by hand. The smart components created automatically (SwoodBox) not only include the 3D model of the hardware for visualization of the project, but also all the necessary machining (holes, cuts etc.) on surrounding panels, making the 3D model ready for production.

Hettich, listed in the IWF Product Finder under Hardware, says it will continue to develop its partnership with Efican for intelligent components for 3D design within Solidworks.

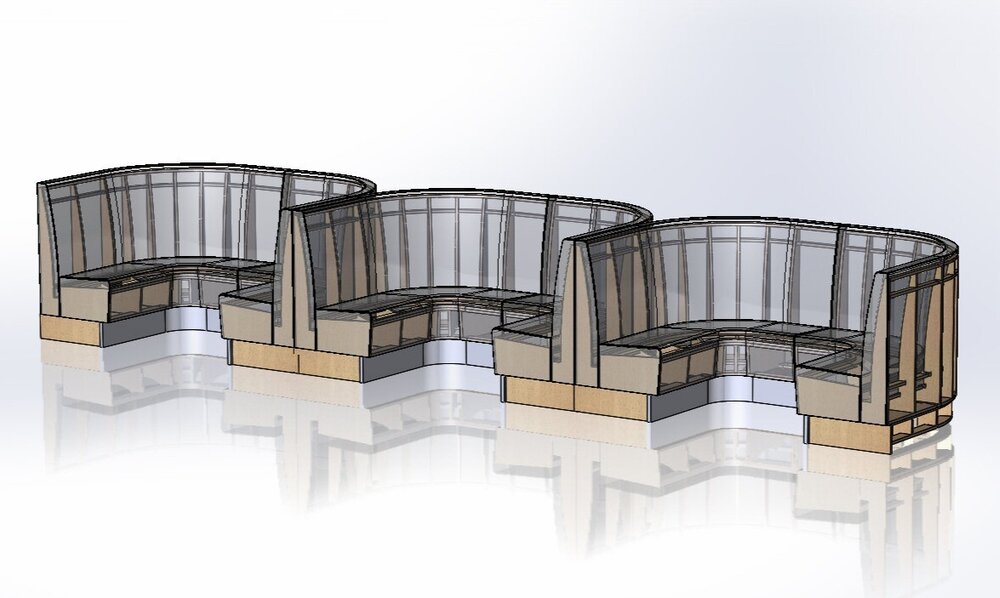

For U.S. wood products firms unfamiliar with Swood by Eficad, the firm is headquartered in La Grande Motte, France and represented by Eficad America Inc. in Boston (617) 669-8755. U.S. users include Kinzel Wood Products, a staircase specialist in Manitowoc, WI; Custom Source Woodworking, an architectural millwork firm in Tumwater, WA; JSI Store Fixtures headquartered in Milo, ME; and V2 Fine Interiors, a San Diego-based specialist in upholstered restaurant banquet seating, including hand-tied spring cushions.

V2 Fine Interiors was founded in 2013 by Victor Vallejo, who says he likes the Swood application because it “allows you to create powerful workflows starting from the design phase to the CAM output without the need of any external programs. We love using Swood because it allows us to leverage the power of Solidworks and Swood features to create advanced adaptable assemblies quickly.”

According to Vallejo, “At V2, all shop drawings are created in 3D allowing for much higher detailed drawings with isometric views that help capture the design intent.” Complex assemblies that can be quickly reused and continually improved upon allow the company to output high quality custom furniture that continues to evolve.

Nearly all wood frame assemblies are cut with CNC routers (a Biesse Rover S 5×12 and a Laguna Smartshop II 4×8) on the plant floor, with the programs linked to “for construction” drawings reducing margin for error. Vallejo says all assemblies are programmed with blind dado joinery, reducing assembly time and increasing frame durability.

Apply to Exhibit

Grow your business at the premier global woodworking trade show.

Show Hours & Location

International Woodworking Fair

Tuesday–Friday

August 6–9, 2024

Tuesday–Thursday

8:30 AM–5:00 PM*

Friday

8:30 AM–2:00 PM*

*Building A opens 7:30 AM Tue-Fri

Georgia World Congress Center

285 Andrew Young International Blvd

Atlanta, GA 30313