Nordfab Expands Dust Extraction Ductwork Manufacturing in Thomasville, NC

February 22, 2022 | Bill Esler

Thomasville, NC—Nordfab Americas began a $5.5 million expansion at its main manufacturing facility in Thomasville, NC, to provide faster shipping and better customer service as it launches Nordfab Now next day shipment.

The project will increase the Nordfab manufacturing footprint to 180,000 sq. ft. of production, office, and warehouse space. Creating 25 new jobs, the project includes a rooftop solar array and additional material handling automation.

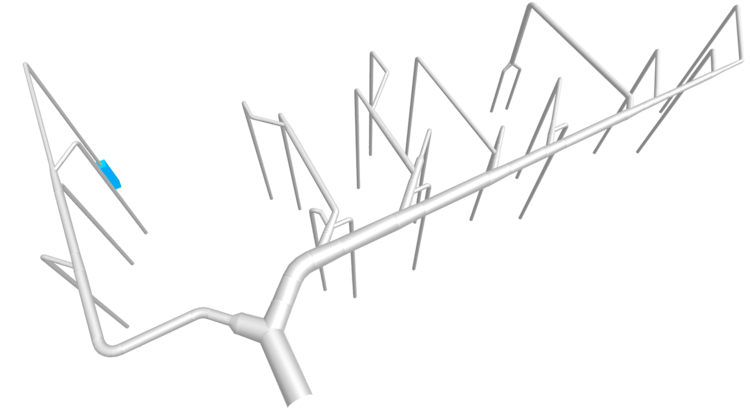

“This expansion project helps us to launch our Nordfab Now program,” says company president Erik Olshall. “When implemented, the Nordfab Now program will allow next day shipment of standard ductwork in dust collection systems designed using our award-winning installation design software, Quick-Fit Visual.”

At IWF 2022, Nordfab (Booth B7379) will show the Quick-Fit program, and its new Drop Out Box, which stops large wood chips in the airstream. Inside the duct, deflectors knock chips downward into a built-in hopper or a waste barrel. The Drop Out Box can be added to Nordfab’s Quick-Fit clamp-together ductwork, which allows fast installation without special tools, rivets, screws, or welding.

In 1990, the company introduced its Quick-Fit clamp-together ductwork, with unique rolled edge ends and easy-to-use clamps. It is now the world’s largest supplier of clamp-together ducting for industrial ventilation. Quick-Fit eases adjustment of ducting layouts during installation as well as easy removal for cleaning, reconfiguring, or relocation. Quick-Fit Visual 2.0 is the next generation of its software for designing dust collection ductwork installations. The new version incorporates features most requested by users, for example:

- Auto addition of reducers and machine adapters

- Ability to select closed off airflow on equipment and nodes

- ability to place components at their minimum distance (overriding the best practice of including a minimum length between components). This allows combinations such as Branch to Branch / Branch to Elbow / Elbow to Elbow.

The expansion rooftop solar system of 1,050 kW will produce an estimated 1,417 megawatt hours of electricity annually, putting it among the five largest solar arrays in its area. Providing roughly 47 percent of the estimated energy consumption at the plant and reducing Nordfab’s carbon footprint by 1,004 metric tons, the equivalent of 218 passenger cars being taken off the road or the energy needed to power 121 homes for a year.

Apply to Exhibit

Grow your business at the premier global woodworking trade show.

Show Hours & Location

International Woodworking Fair

Tuesday–Friday

August 6–9, 2024

Tuesday–Thursday

8:30 AM–5:00 PM*

Friday

8:30 AM–2:00 PM*

*Building A opens 7:30 AM Tue-Fri

Georgia World Congress Center

285 Andrew Young International Blvd

Atlanta, GA 30313