Mohawk Invests $87 Million in NC Laminate Plant

November 22, 2021 | Bill Esler

Thomasville, NC—Mohawk Industries, Inc. (NYSE:MHK) will invest $87 million to expand its laminate flooring manufacturing facility in Thomasville, NC, acquired from Unilin in 2005.

With $9.5 billion in global flooring sales last year, Mohawk will add the new building to its existing state-of-the-art manufacturing facility in Thomasville to increase laminate flooring production in North Carolina, where it employs 1,000 people. About 87 new jobs will be created with the expansion. Mohawk employs 19,600 in the U.S. and 42,000 worldwide.

“Our laminate and wood business continues to grow, though our sales were restricted by our capacities,” says Chris Wellborn, Mohawk COO, during the latest quarterly earnings interview. “Our new laminate line should be operational by the end of this year to expand our sales and provide more advanced features. Chemical shortages limited our laminate production in the period as we responded by re-engineering our formulations to maximize our output.”

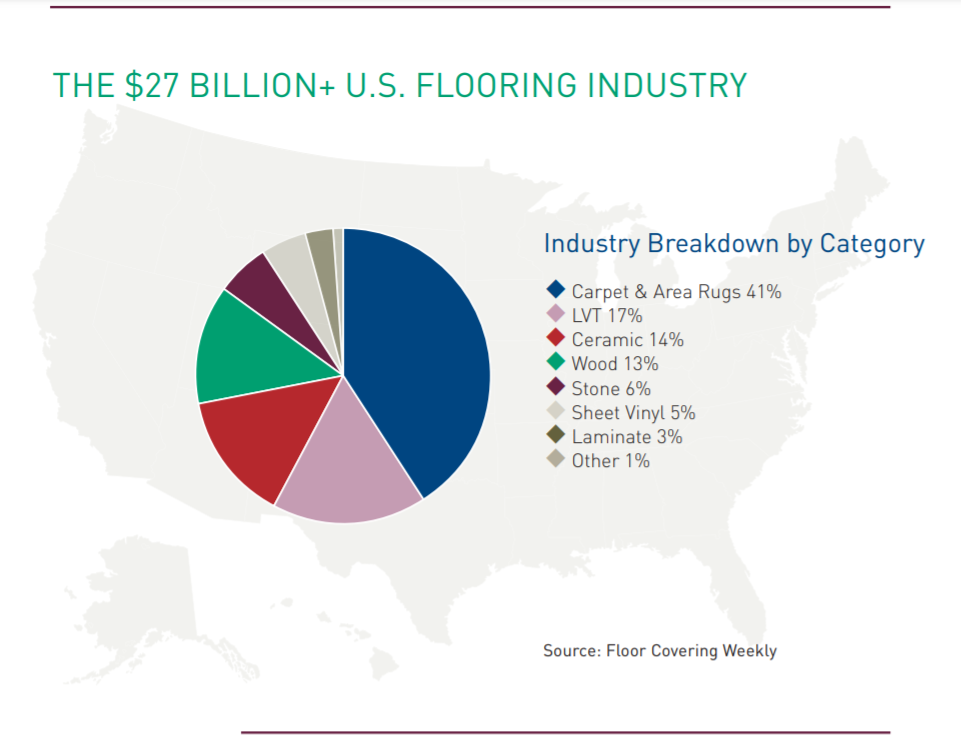

Mohawk was predominantly in the carpet business until 10 years ago, but moved increasingly into ceramic, resilient, and wood-based flooring as it expanded through acquisitions around the world. The flooring company cites industry-wide U.S. flooring sales breakdowns showing laminates and wood flooring totaling 16 percent market share. Fast-growing LVT [Luxury Vinyl Tile], which can simulate the look of wood and is fabricated and shaped on similar CNC machinery, totals 17 percent. In square footage, wood is 6.7 percent of the total; laminate is 4 percent. Mohawk says it is the largest U.S. producer of laminate flooring and among the largest wood flooring firms.

Mohawk introduced innovations such as HydroSeal™ water-resistance that extended the laminate category into kitchens and baths, and more realistic visuals with GenuEdge® pressed bevel edges and surface embossing in register that it feels precisely recreates the appearance of wood. As consumer preference for waterproof flooring increased, Mohawk introduced a proprietary technology called WetProtect™ that makes the joints of installed laminate water-tight and prevents liquid spills from reaching the subfloor. This same technology has been applied to its solid wood flooring with UltraWood™, which also features a waterproof finish in addition to improved scratch, wear, and dent resistance

In its third quarter, Mohawk Flooring reported $2.8 billion, up 9.4 percent worldwide. Its North America sales just exceeded $1 billion, a 6.9 percent increase. Challenges in finding workers, sourcing raw materials, and shipping finished product put constraints on Mohawk, which it is addressing by redesigning and reformulating products, and expansions such as the one in Thomasville. COVID-19 in particular complicates the labor supply for Mohawk. It reported $3.6 billion in North American flooring sales in 2020, which fell $249.6 million—6.5 percent—due to COVID-19.

“Rather than improving as we expected, the availability of labor, materials, and transportation became more challenging, resulting in higher costs,” says CEO Jeff Lorberbaum in a third quarter 2021 earnings analysis. “Tight chemical supplies, in particular, reduced the output of our LVT, carpet, laminate, and board panels.” It affects the U.S., where Mohawk has 14 plants, along with global operations.

“While we are presently seeing COVID cases declining in most of the regions, many of our operations experienced increased absenteeism during the period, affecting our efficiencies in production,” Lorberbaum says. “For the near term, we do not see any significant changes in these external pressures.”

Apply to Exhibit

Grow your business at the premier global woodworking trade show.

Show Hours & Location

International Woodworking Fair

Tuesday–Friday

August 6–9, 2024

Tuesday–Thursday

8:30 AM–5:00 PM*

Friday

8:30 AM–2:00 PM*

*Building A opens 7:30 AM Tue-Fri

Georgia World Congress Center

285 Andrew Young International Blvd

Atlanta, GA 30313