Is Powder Coated Wood Poised for Its Next Big Advance?

March 1, 2021 | Bill Esler

Pittsburgh, PA – Powder coatings might be nearing a tipping point that could dramatically increase their use as a supplement or even a replacement for liquid coatings in manufactured wood products.

Renowned for their toughness and durability when used over metal – notably automobile wheels – application on engineered panel and solid wood was hampered due to requirements for high heat levels in the curing ovens. Powder coating is also often applied with an electrostatic assist, and wood is far less conductive for carrying a charge.

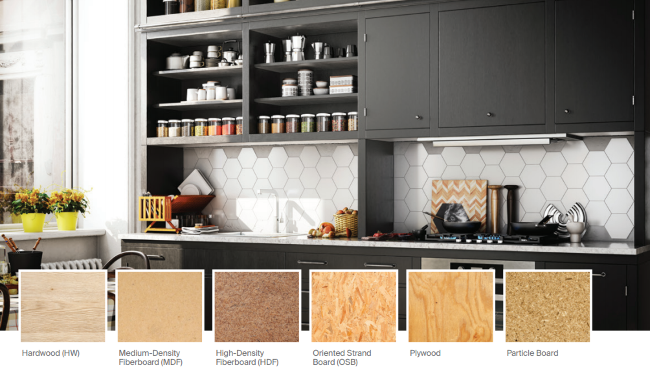

Applications for PPG Envirocron HeatSense powder coatings include a range of wood and panel.

Earlier powder coating requirements for high heat to cure were problematic for use on particleboard or MDF. The heat can weaken the binding adhesives and all wood products are prone to shrink, swell, or warp, which has caused cracking in powder coatings. Solid wood has inherent variations in moisture, and this too creates a tendency for cracks after powder is fused to the surface.

But powder coating materials and curing systems manufacturers have been developing formulations to get the coating to fuse with less heat. In 2007, DVUV introduced UV cured powder coating ovens, intended for MDF. A few years later, IGP introduced powders that fused at lower temperatures, from 400 down to around 250 degrees and Axalta introduced Alesta decorative powder coatings that fuse at lower temperatures, suitable for some wood applications. As the market for powder coated wood products began to expand, uses expanded to include cabinets intended for garages, or high wear settings in retail display.

Another sign of the advance of powder coating was the acquisition last year of Alpha Coatings by PPG Industrial Coatings. Shelley Verdun was named PPG Business Manager, Powder Coatings with a mission to expand the business in all sectors.

In November last year, PPG introduced PPG Envirocron HeatSense powder coatings for heat-sensitive wood and wood-composite substrates. PPG expects these coatings — which cure at 150 to 250 degrees, coupled with a perfected, strictly regimented application and curing process — to overcome the traditional barriers to powder coating wood.

Les Smith, who left Sherwin-Williams to take up the role of PPG Business Development Manager for powder coatings beginning March 1 joins Verdun to advance powder coating on wood. Smith sees powder coating as viable for a number of practical uses. “Powder coats completely cover and seal wood,” Smith says, so their use as a primer can reduce sanding on white wood. It could also be used to speed components into final coatings and paints.

For certain settings, such as medical offices, Smith believes powder coating would be more hygienic and durable.

“When you have seamed material and a base and an edgeband, there is no way to encapsulate that wood,” says Smith. “The powder encapsulates everything.”

Apply to Exhibit

Grow your business at the premier global woodworking trade show.

Show Hours & Location

International Woodworking Fair

Tuesday–Friday

August 6–9, 2024

Tuesday–Thursday

8:30 AM–5:00 PM*

Friday

8:30 AM–2:00 PM*

*Building A opens 7:30 AM Tue-Fri

Georgia World Congress Center

285 Andrew Young International Blvd

Atlanta, GA 30313