Huber Engineered Woods Plans New Mill for OSB Subflooring

February 9, 2022 | Bill Esler

Cohasset, MN—Huber Engineered Woods is advancing development on a new $440 million mill that will make oriented strand board (OSB) for its AdvanTech subflooring panels and other engineered panel.

The subsidiary of J.M. Huber—a company known for edgeband adhesives and Liquid Nails among other products—said the facility will be built in Cohasset, MN, to increase production of ZIP System® and AdvanTech® structural panels.

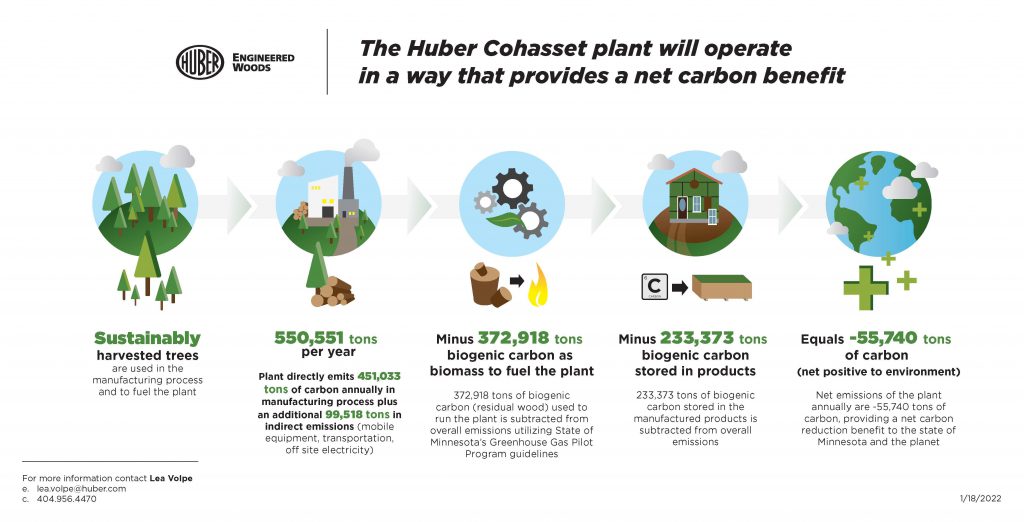

It issued a revised Environmental Assessment Worksheet showing the plant will generate negative CO2 emissions due to the carbon sequestering characteristics of wood products; and using of wood scrap for fuel. The plant will emit 550,551 tons of CO2 annually, but that is offset by using wood scrap for energy (-372,918 tons of CO2) and storing CO2 in the end wood products (-233,373). This calculation results in -55,740 tons of CO2 emitted annually.

An exhibitor at IWF 2022, Huber Engineered Woods (IWF Booth C2114) introduced AdvanTech X-Factor Subflooring Panel in February 2021, then announced plans for the mill in June.

Huber’s AdvanTech X-factor has gained popularity among builders for improving performance on wood flooring. It features a built-in protective top layer that carries a Squeak-Free Guarantee. Common oriented strand board (OSB) and plywood panels can show flaking, delamination, or discoloration from exposure to daily jobsite stress, which then affects the finished wood floor installed atop it. AdvanTech X-Factor protects the panel surface quality and appearance. Huber says the built-in, water-shedding top layer provides a smooth, even subfloor surface.

Huber Woods also offers TruSpec, a precision engineered panel specifically for the architectural door and millwork industry. Each product is manufactured by thermally fusing cross-oriented wood strands with a water-resistant adhesive, offering a stronger, flatter, more stable product. The core is said to be free of voids with uniform density.

The new OSB plant will hire 150, and is expected to boost adjacent local industries including timber and trucking the fiber source. Huber had been negotiating for the site, and for governmental agency support. Following local hearings on environmental issues, Huber Woods issued the new Environmental Assessment Worksheet that underscores the health of Minnesota forests as a fiber supply and the environmental benefits of wood products manufactured at the plant.

The mill will be Huber’s sixth in the U.S. (others are located in Georgia, Maine, Tennessee, Oklahoma, and Virginia) and supports the growing needs of single-family, multifamily and commercial builders along with select OEM industries.

Apply to Exhibit

Grow your business at the premier global woodworking trade show.

Show Hours & Location

International Woodworking Fair

Tuesday–Friday

August 6–9, 2024

Tuesday–Thursday

8:30 AM–5:00 PM*

Friday

8:30 AM–2:00 PM*

*Building A opens 7:30 AM Tue-Fri

Georgia World Congress Center

285 Andrew Young International Blvd

Atlanta, GA 30313