Engineered Floors LLC Adds Digital Printing Line at Its Dalton Plant

December 7, 2021 | Bill Esler

Dalton, GA—Engineered Floors LLC, a Dalton, GA company headed by Robert E. Shaw, has ordered a Hymmen Jupiter digital printing line, the first U.S. flooring firm to do so.

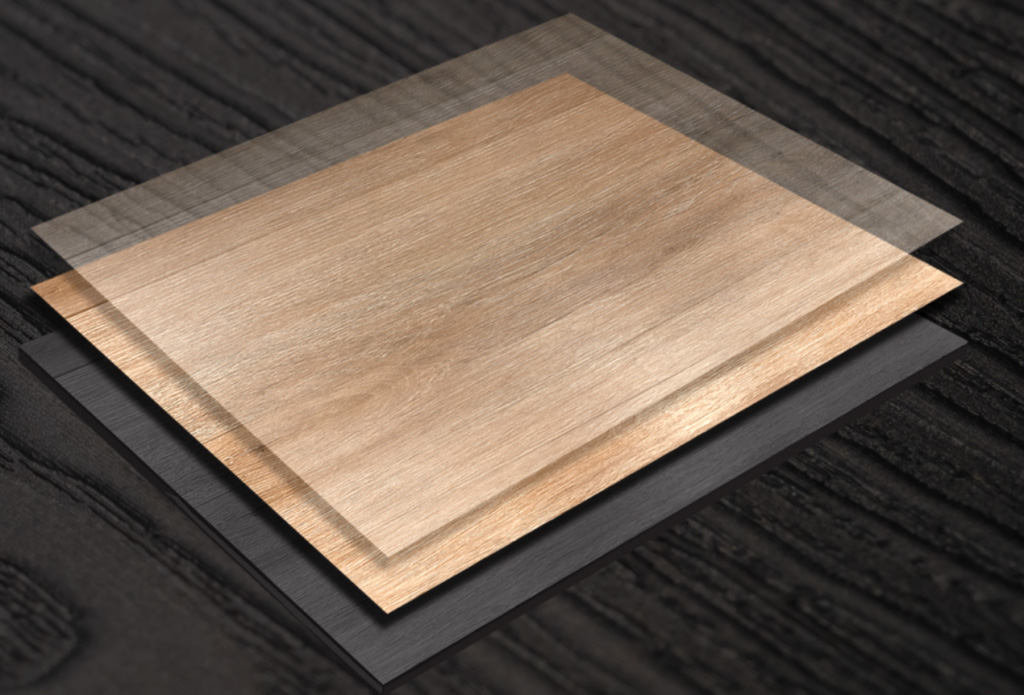

The Hymmen Jupiter digital printing line will be used in the production of multi-layer modular Luxury Vinyl Tile (LVT) at Engineered Floor’s 1.2 million-sq.-ft. Seretean plant in Dalton. Engineered Floors announced last year it would initiate domestic U.S. LVT production at Seretean “using the latest and most innovative manufacturing equipment available,” with a complete revitalization of the plant. The order is coupled with a digital printing and intellectual property licensing agreement with i4F, a Hamont, Belgium firm which manages licensing for Hymmen and other flooring technology suppliers.

“High quality digitally printed flooring is the future and now Engineered Floors is pioneering that shift by producing all multilayer modular flooring to digital printing,” says i4F CEO John Rietveldt. “Hymmen digital printing technologies produce the world’s most advanced flooring and are exclusively available via an i4F license.” (On November 25, Hymmen won a patent infringement suit against Barberan, a competitor in digital printing.)

“The latest innovation and technology has always been important to us,” says Shaw, chairman and CEO of Engineered Floors. “Our customers can expect high-quality, stylish products made with disruptive technology like digital print LVT. We will continue to innovate.”

Engineered Floors already offers a digitally printed engineered floor line, Ensignium, which does not use printed films nor PVC wear layers. Instead the wood grain is digitally printed directly on a dimensionally stable stone composite core. High definition scanning technology captures the image of real wood. Advanced digital printing replicates the visual look as well as the three-dimensional contoured surface. A minimal pattern repeat (1 in 30) makes the floor look natural and authentic.

“We are delighted to welcome Engineered Floors to Hymmen’s world of superior digital printing,” says René Pankoke, managing partner of Hymmen. “This has only been made possible thanks to our partnership with i4F. As our exclusive licensing partner, i4F ensures freedom to operate under the patents in its digital printing cluster in the United States and beyond.”

i4F develops patents and technologies for the flooring industry. Its portfolio includes intellectual property for flooring installation and wall mounting systems, material compositions, surface treatment, and digital printing, as well as laminate and board production technologies. i4F has strategic partnerships with the industry’s most important IP players, including Classen, Kronospan, HMTX, Windmöller, CFL Flooring, Tarkett, Kingdom Flooring, Lico, Benchwick, QuickStyle Industries, Shaw Industries, as well as Hymmen. Its flagship technologies, 3L TripleLock® and Click4U®, provide a unique one piece drop-lock installation technique for flooring panels that eliminates the need for an additional insert on the short side. The solution is suitable for laminate, luxury vinyl tiles, expanded polymer core, solid polymer core, and wooden flooring panels. International patents and patent applications for i4F’s technologies have been granted and filed in over 100 countries worldwide.

Hymmen produces industrial production technology for the production of board materials or the surface finishing of board or roll materials. With 200 employees worldwide, Hymmen works on investment projects in furniture, flooring, doors, decorative laminates, and other building materials. Technologies include industrial press and calender lines, liquid coating and lacquering, as well as industrial digital printing lines, and automation and control technology. Since 2008 Hymmen has focused R&D on industrial digital printing. With more than 45 operating digital printing lines worldwide and a cumulative sales volume of more than €100 million, it is a market leader in the woodworking industry. The latest developments in digital printing include process optimization in decor printing with UV-curing inks as well as the digital surface structure (Hymmen DLE plus).

Apply to Exhibit

Grow your business at the premier global woodworking trade show.

Show Hours & Location

International Woodworking Fair

Tuesday–Friday

August 6–9, 2024

Tuesday–Thursday

8:30 AM–5:00 PM*

Friday

8:30 AM–2:00 PM*

*Building A opens 7:30 AM Tue-Fri

Georgia World Congress Center

285 Andrew Young International Blvd

Atlanta, GA 30313