Düspohl Introducing New Wrapping and Laminating Solutions

April 4, 2023 | Warren Shoulberg

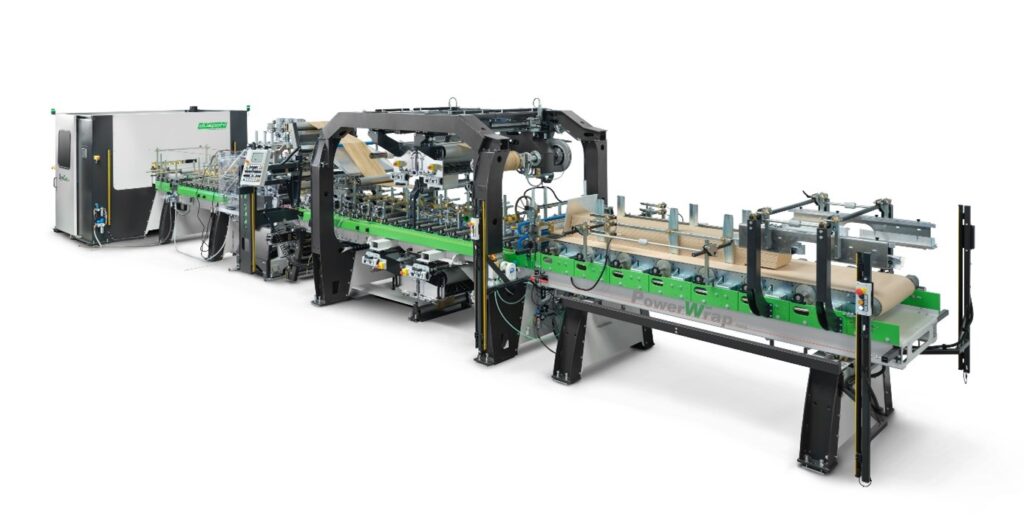

German-based Düspohl Maschinenbau is introducing new improved solutions and standards for wrapping and laminating larger wood pieces.

With new “scalable solutions,” Düsphol says it will be offering “its profile wrappers with optimized standard equipment that reduces set-up times, simplifies the handling and minimizes downtimes.”

The profile wrapping and laminating lines manufacturing company, based in Schloss Holte-Stukenbrock, Germany and serving customers around the world, says it is focusing on innovative technologies it has developed for optional solutions to automate the process.

“The degree of automation is scalable according to the customers’ demands and project requirements,” it said. “That way, users always obtain the ideal combination of investment volume and equipment. Of course, common interfaces, for example according to the OPC UA standard, will be supported.”

In explaining its process, Düsphol, which develops and manufactures profile wrapping lines and laminating lines including related machines like slitting machines and parquet presses, said profile wrapping involves a decorative surface that is laminated onto a substrate in linear form. This is done by means of a profile wrapping machine. Most substrates are made from wood (composites) or PVC. Surface materials can be paper, PVC or – more classic – veneer and other suitable material. Pieces for furniture, kitchens, shelves, skirting boards, window frames, door frames and shutter are typical applications.

Apply to Exhibit

Grow your business at the premier global woodworking trade show.

Show Hours & Location

International Woodworking Fair

Tuesday–Friday

August 6–9, 2024

Tuesday–Thursday

8:30 AM–5:00 PM*

Friday

8:30 AM–2:00 PM*

*Building A opens 7:30 AM Tue-Fri

Georgia World Congress Center

285 Andrew Young International Blvd

Atlanta, GA 30313