Cornerstone Specialty Wood Doubles Shelf and Flooring Capacity

December 17, 2021 | Bill Esler

Louisville, KY—Cornerstone Specialty Wood Products is nearing completion of a new, $15 million facility for production of its ResinDek engineered wood flooring panel and shelving products.

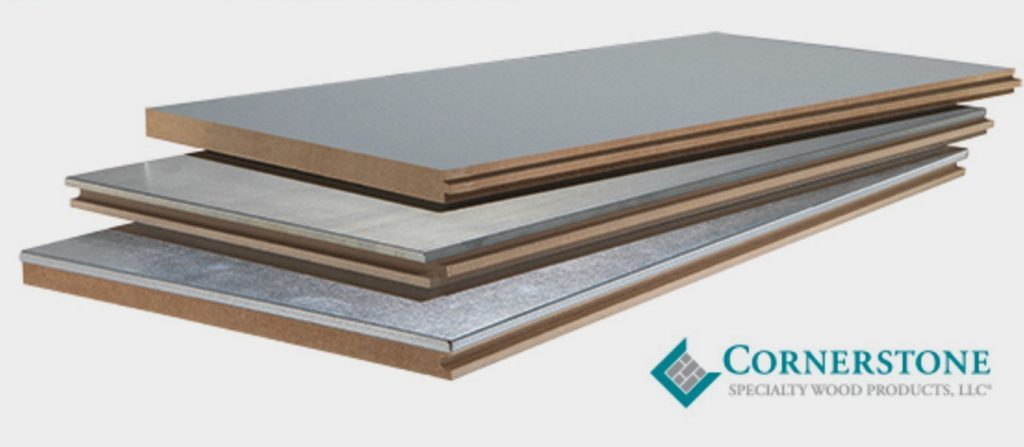

The nearly 180,000-sq.-ft. plant will allow Cornerstone to double capacity for producing ResinDek, a heavy-duty engineered flooring panel made from a proprietary sandwich of moisture-resistant MDF and HDF. A unit of Universal Woods, Cornerstone’s greenfield manufacturing facility is located at a logistics hub at the edge of Louisville, KY, near the UPS Worldport and the Louisville International Airport.

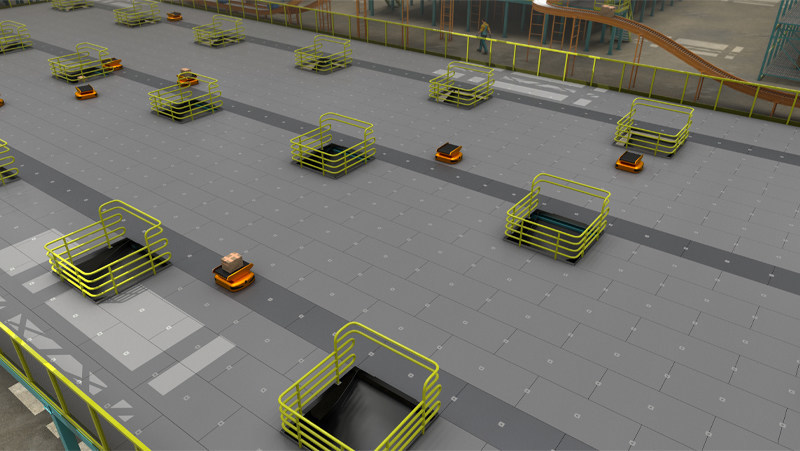

ResinDek was invented by Greg Doppler, president of Cornerstone. The industrial engineered flooring panels are used widely in warehouses to create uniform working levels for workers, materials handing systems, and packaging convenyors. The floor panels support live and dead pallet jack limits from 2,000 – 8,000 lbs. and the rigorous demands of Automated Guided Vehicles and Autonomous Mobile Robots.

“Our business has grown dramatically over the past two years,” says Doppler. “We are approaching the upper limits of our current production capacity.”

One reason for the spike in demand was the August 2021 introduction of a warehouse picking and storage product, ResinDek, used to store and support cartons of goods in a warehouse or manufacturing center. And the rise in online sales during the COVID-19 pandemic sparked a flurry of warehouse and distribution center construction, the prime customers for ResinDek.

Fully customizable, the ResinDek Shelving System is comprised of three components: ResinDek horizontal shelving, ResinDek vertical dividers, and lumber supports that span the distance of the rack beams. Each system can be designed to accommodate shelf heights from 6 to 20 inches, depths from 8 to 60 inches, and vertical divider spaces from 4 to 48 inches on center. Because they are custom machined, the dividers can be snapped into place, no fasteners, screws, or other hardware required.

The new facility will carry more inventory, and new production lines will speed operations. “That, combined with a design that incorporates significantly more dock doors for shipping and receiving, will allow us to reduce lead times,” says Scott McGill, director of sales at Cornerstone.

The latest state-of-the-art versions of electron beam coating and curing equipment that Cornerstone uses to apply protective coatings and finishes will be included in the production lines, “only at much higher throughput rates and volumes than before,” Doppler say. “It will also allow us to attain even greater quality than the high standards [of] our current coating and curing line.”

The production staff at the existing Cornerstone operation increased headcount in 2021 in anticipation of the expanded production capacity. “Starting them ahead of the new plant’s construction allows them to become familiar with the ResinDek production process before the new facility goes live,” says Doppler.

Equipment is slated to be installed and commissioned throughout January 2022, with partial production beginning shortly thereafter. The new coating and curing machinery is scheduled for installation in the second quarter of 2022.

For more than 20 years, Cornerstone Specialty Wood Products, LLC has been at the forefront of research and development in the field of engineered wood floor panels for the material handling industry. Parent company Universal Woods also owns R&D Coatings, ChromaLuxe, which manufacturers wood and metal substrates for archival printing and signage, as well as sublimation transferred images for tabletops.

Apply to Exhibit

Grow your business at the premier global woodworking trade show.

Show Hours & Location

International Woodworking Fair

Tuesday–Friday

August 6–9, 2024

Tuesday–Thursday

8:30 AM–5:00 PM*

Friday

8:30 AM–2:00 PM*

*Building A opens 7:30 AM Tue-Fri

Georgia World Congress Center

285 Andrew Young International Blvd

Atlanta, GA 30313