Cambridge Kitchens Mfg. Adds Biesse CNC and Stiles Saw

October 10, 2021 | Bill Esler

Hicksville, NY—Cambridge Kitchens Mfg. added two new manufacturing machines to its Hicksville, NY production facility, a move owner Nick Vassi says further refines its highly customized kitchen creation process.

The added equipment includes a Rover A CNC router from Biesse, and a Homag Sawteq B-400 panel saw from Stiles Machinery. Founded in 1993, Cambridge Kitchens specializes in designing, manufacturing, and installing premium, fully custom cabinetry.

Owner Nick Vassi says Cambridge Kitchens creates premium custom cabinetry by leading customers through a layer-by-layer design process, then crafts components with computerized equipment guided by artisans. A certified dealer of Sub-Zero and Wolf kitchen appliances, Vassi says his firm fully integrates technology into the design, approval, and production process.

“Our design process has always been incredibly elaborate. Careful attention is given to every little detail,” Vassi says. “We begin with an in-depth meeting, often spending hours to ensure that their dream kitchen comes to life by meeting all their requests.”

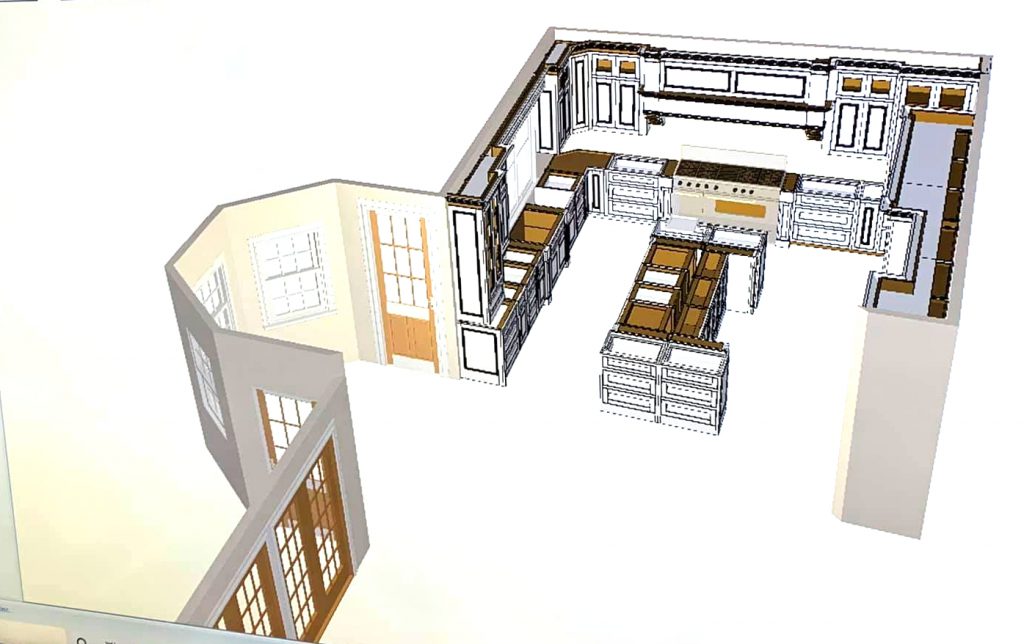

Through 3D computer renderings created right before their eyes, clients can experience how their kitchen will look before anything is built. “This allows us to give them a sense of the final product, adding details and building exactly what they want before we even move on to manufacturing,” says Vassi.

Every single detail of the kitchen is mapped out in granular detail before the approval for production, including door style selections, color selections, architectural details, and planning exactly where pots, pans, and utensils will be stored. Once a client is satisfied with the plans, they sign off before production before the pieces are individually built in Cambridge Kitchen’s production facility.

The high-tech computer design technology communicates directly with machinery in the factory. Components are fashioned from the finest solid woods, fitted with European hinges, and finished with hard acrylic paints that will not chip, discolor, or oxidize. Once approved, turnaround times are quick, with a kitchen manufactured in two to three weeks. Clients are then asked to come in and inspect the entire design, fully assembled, before installation begins in the home.

“We offer far more than just cabinets,” Vassi says. “We create an experience for our clients using a wide variety of important touches to spin a little magic into each project design. Clients can choose anything they want during the design process, from custom colors to custom door styles. We achieve both high-end aesthetics and functionality. Our greatest strength is turning ideas into works of enduring beauty—by combining both traditional and nontraditional methods.”

Apply to Exhibit

Grow your business at the premier global woodworking trade show.

Show Hours & Location

International Woodworking Fair

Tuesday–Friday

August 6–9, 2024

Tuesday–Thursday

8:30 AM–5:00 PM*

Friday

8:30 AM–2:00 PM*

*Building A opens 7:30 AM Tue-Fri

Georgia World Congress Center

285 Andrew Young International Blvd

Atlanta, GA 30313