Cabinetry and Millwork Designs Help Offsite Home Building Catch On

December 31, 2021 | Bill Esler

Maryville, TN—Clayton Home Building Group, which has a vibrant business in factory-built homes, says it is increasing “transparency” by showcasing its sustainable, high-quality build process in display homes at its retail locations across the country.

The “Behind the Build” initiative shows how plumbing, electrical, paneling, flooring, and millwork are installed, and of course, kitchen cabinetry. (Clayton’s house cabinet brand is DuraCraft.)

A national builder of traditional site-built and off-site built homes, Clayton’s move may run counter to traditional approaches by factory-built sellers, some of whom have been known to obfuscate the homes’ origins in factories to avoid unfavorable associations with double-wide trailers and traditional mobile homes.

Instead, Clayton is showing “behind the scenes” videos to showcase innovation, efficiency, and quality of its off-site built construction standards, building materials, and home products. And the newest crop of millennial first-time home buyers may find the approach desirable, both financially (they are significantly lower in prices) and in terms of the purchase process. A manufactured home averaged $100,000 in 2020—not including land—while site built homes averaged $400,000, though that figure includes land.

In 2020, Clayton built 56,240 homes across the country, more than 20,000 of them produced in its 40 U.S. factories as off-site, factory- built homes—including manufactured homes, modular homes, CrossMod™ homes, Designer Cottages and PMRVs. It also opened an interior door manufacturing center in Morristown, TN capable of producing 8,000 doors a day.

“Off-site built homes are a modern, quality option for anyone looking to buy a home,” says Kevin Clayton, CEO of Clayton. “These affordable homes are energy efficient and stylish, though many people aren’t aware of the level of craftsmanship built into each design. The ‘Behind the Build’ experience highlights the benefits the off-site home building process offers home buyers as they make one of the biggest purchasing decisions of their lives.” Homes are sold at some 350 company-owned outlets as well as other home sellers.

The shift in positioning for Clayton’s factory-built housing coincides with the growing numbers of millennial generation first-time home buyers, for whom price-point is a key concern. Factory-built housing is generally less expensive than site-built homes. These buyers do not have the same expectations as previous waves of first-time purchasers, and are more willing to examine factory-built homes on their own merits.

In a 2019 survey of 4,000 recent home buyers, the top elements influencing a purchase were laundry rooms, hardwood floors, energy efficiency, and open plan kitchens. Sales outlets for manufactured homes can readily display name brands of hardwood flooring, laundry room designs with well-established appliance brands, and stoves, refrigerators, and microwave ovens with Energy Star® ratings.

But kitchen and bath cabinetry, and interior millwork are another matter. These items tend to be built in home builders’ plants, to minimize supply chain issues, and to match manufacturing specifications required by the plant. Cabinets in factory built homes are supplied in three ways:

- First are home-building factory-built cabinets: They are built to the factory specifications without being governed by a third party.

- Second are KCMA Stamp: These cabinets are constructed at the factory but are built to the KCMA (Kitchen Cabinet Manufcturers Association) standards. This is the same standard used by all certified cabinet manufactures for site-built homes as well.

- Third is a cabinet constructed by a third party cabinet manufacturer: These pre-built cabinets are shipped to the factory and installed.

According to experts, the first two cabinet types usually have oak cabinets as their base model, with an option to upgrade to a stained maple cabinet. Option number three gives buyers the greatest number of cabinet choices, but also tends to be the most expensive.

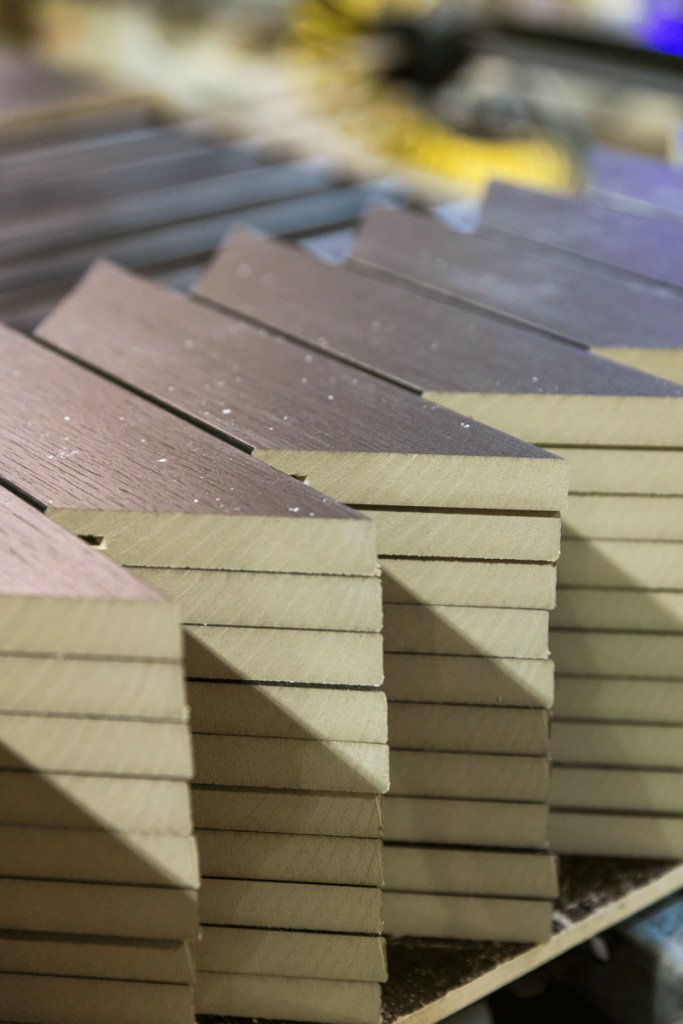

Cabinet brands are often localized or regionalized, and don’t have the same national or global branding cache. Perhaps for this reason, Clayton established its DuraCraft cabinets and Luxe interior door lines. Its DuraCraft cabinetry surfaces are made from a sturdy, water-repellent material developed in Europe that is exclusive to Clayton Built homes in the off-site housing industry. “DuraCraft cabinets are assembled using modern machinery and installed by hand at a Clayton home building facility with precision and care,” Clayton says.

Home sales centers stocking Clayton Built homes feature interactive QR codes throughout its models. During a tour, potential buyers can scan codesdszx to discover and explore the series of videos that explore energy efficiency, sealed construction, structural integrity and plumbing. This will provide customers the tools necessary to select a floor plan while discovering how manufactured and modular homes are some of the most affordable, reliable and beautifully designed options for home ownership today.

These cabinets are designed to be unique and beautiful with fresh, on-trend colors, giving your spaces the look and feel you want.

The Behind the Build digital experience is part of the larger Clayton Built® Promise of strength, integrity and accountability. All Clayton Built® homes are a step above standard federal guidelines, and include the following features that improve overall quality, efficiency and durability:

Apply to Exhibit

Grow your business at the premier global woodworking trade show.

Show Hours & Location

International Woodworking Fair

Tuesday–Friday

August 6–9, 2024

Tuesday–Thursday

8:30 AM–5:00 PM*

Friday

8:30 AM–2:00 PM*

*Building A opens 7:30 AM Tue-Fri

Georgia World Congress Center

285 Andrew Young International Blvd

Atlanta, GA 30313