3D Printing of Building Panels Wins $4M Research Grant

November 1, 2021 | Bill Esler

Moscow, ID—A University of Idaho College of Engineering professor will head research into developing technology to turn wood waste into prefabricated engineered panel for roofing, flooring, and walls.

An interdisciplinary research team led by College of Engineering Assistant Professor Michael Maughan has been awarded nearly $4 million from the National Science Foundation’s (NSF) EPSCoR Research Infrastructure Improvement Program.

Maughan and the University of Idaho team has been working under state grant funding in collaboration with the College of Art and Architecture’s Integrated Design Lab and the College of Natural Resources since 2019. It developed an advanced 3D-printing technology using a binding agent and wood fibers not used by the lumber market, such as waste wood and sawdust from mills and wood processing plants.

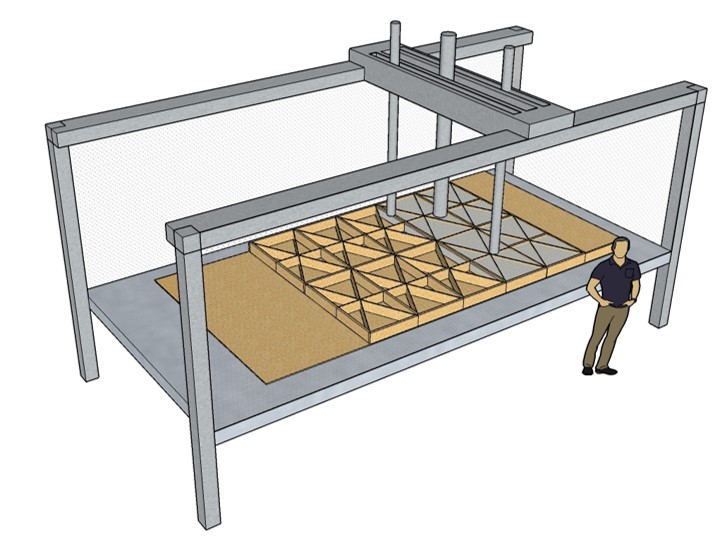

As part of the NSF funding, researchers from Auburn University will join the team to continue to refine the binding agent used in the renewable material. Funding through 2025 supports further development and testing of an additive manufacturing process and the design and construction of a 3D printer capable of producing modular wall, floor and roof panels printed from wood for industrial construction.

“We’re developing a new composite material, using completely bio-based resources on a truly large scale,” Maughan says. “With this technology, houses and commercial buildings can be made entirely differently.” Maughan told IWF Network News he foresees fully fabricating walls, with cut-outs and contours to house utilities, for installation at the construction site. Using wood waste, “We can push past climate change, mitigate impact on our environment and make better use of the natural resources we have,” says Maughan.

The University of Idaho has been constructing other sustainable buildings, including the Idaho Central Credit Union Arena, the country’s first mass engineered wood venue of its kind, which is scheduled to open in November, built with LVL and CLT panel. U of I’s research partner Auburn University recently received a USDA grant for research on incorporation of steel connectors in fabricating mass wood construction components.

The multi-year, 3D-printing technology project is expected to positively impact Idaho’s fast-growing construction industry. According to the U.S. Energy Information Administration, 60 percent of global waste is produced from the construction sector. With unique carbon sequestration potential, this new 3D-printed material is expected to reduce that significantly, Maughan says.

The research focuses is on the structural properties of additive manufactured wood materials and continued testing of the material’s resistance to fire, water damage, pests, and other degrading agents, improving its ability to stand the test of time.

Despite rapid urbanization globally, Maughan says the U.S. construction industry experiences productivity losses of hundreds of billions per year.

“Housing construction has very low productivity in terms of time invested and return,” he says. “When you build a house, the contractors show up, they have to lift up the structure, frame it in. A number of things can disrupt the process — weather, manpower, tools, skill sets. It’s all very inefficient.”

Apply to Exhibit

Grow your business at the premier global woodworking trade show.

Show Hours & Location

International Woodworking Fair

Tuesday–Friday

August 6–9, 2024

Tuesday–Thursday

8:30 AM–5:00 PM*

Friday

8:30 AM–2:00 PM*

*Building A opens 7:30 AM Tue-Fri

Georgia World Congress Center

285 Andrew Young International Blvd

Atlanta, GA 30313