IWF Woodworking Today

Unlocking the Value of Wood Waste Recycling

November 1, 2023 | Dan Wellens

In the realms of woodworking and manufacturing, the need for resource efficiency and sustainability has gained paramount importance. A significant aspect of this movement revolves around effectively managing wood waste material and converting it into a valuable resource. Companies such as RUF Briquetting Systems have taken the lead in offering a straightforward yet highly effective solution that transforms waste into a source of revenue.

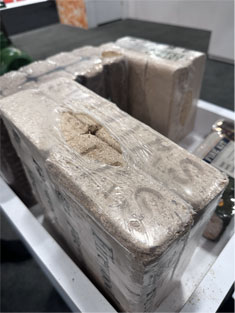

RUF Briquetting Systems specializes in the art of briquetting, a process that employs hydraulic pressure to compact and reshape various waste materials into dense, high-quality bricks known as briquettes. These briquettes can be crafted from a wide range of materials, including wood scraps, metal shavings, and biomass residues. The outcome is a condensed and manageable waste form that can be conveniently stored, transported, and sold at a premium.

The economic advantages of adopting a briquetting system are substantial. By converting wood waste and other materials into briquettes, companies can open up new revenue streams. These briquettes hold market value, making them sought-after commodities across diverse industries. Instead of being a drain on resources, your waste materials can become a source of income.

Furthermore, the briquetting process aids companies in saving money by promoting the recycling and reutilization of raw materials. Rather than discarding valuable resources as waste, these materials are reclaimed and transformed into briquettes. This not only reduces disposal costs but also minimizes the necessity of purchasing fresh raw materials, leading to substantial long-term savings.

As the global focus on environmental consciousness grows, businesses face increasing pressure to diminish their ecological impact. Briquetting enables companies to efficiently handle their waste, contributing to a more sustainable and eco-friendly operation.

A particularly noteworthy aspect of RUF Briquetting Systems is their capacity to recover cutting fluids employed in the manufacturing process. Remarkably, companies can reclaim up to 97% of these cutting fluids for future use. This achievement bears significance in both cost savings and environmental responsibility. Through the recycling of cutting fluids, companies reduce expenses associated with procuring new fluids while simultaneously minimizing the generation of hazardous waste.

Wood waste material should no longer be regarded merely as a discardable byproduct. Instead, it signifies an opportunity to create value and contribute to a more sustainable future. Companies like RUF Briquetting Systems have exemplified the transformative potential of briquetting, enabling businesses to convert their waste into revenue, economize, achieve sustainability targets, and even recover cutting fluids for future use. By embracing wood waste recycling, companies can unlock latent potential and progress toward a more prosperous and environmentally responsible future. Visit www.ruf-briquetter.com to find the right machine for your company’s needs.

Apply to Exhibit

Grow your business at the premier global woodworking trade show.

Show Hours & Location

International Woodworking Fair

Tuesday–Friday

August 6–9, 2024

Tuesday–Thursday

8:30 AM–5:00 PM*

Friday

8:30 AM–2:00 PM*

*Building A opens 7:30 AM Tue-Fri

Georgia World Congress Center

285 Andrew Young International Blvd

Atlanta, GA 30313