IWF Woodworking Today

Cobots Revolutionizing Woodworking: A New Era of Collaboration

September 6, 2023 | Dan Wellens

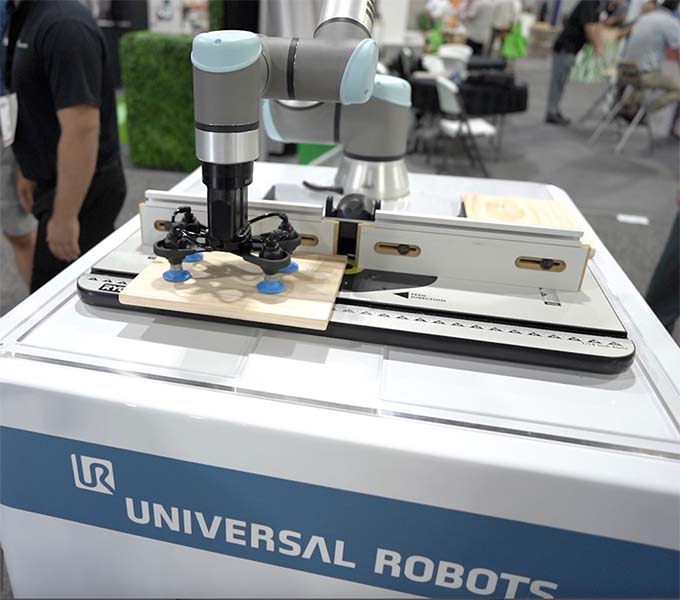

Warp-speed technology advances are transforming the woodworking industry thanks to the emergence of collaborative robots—often referred to as cobots. These innovative machines, such as the UR10e Arm by Universal Robots and the Productive Robotics OB7, are ushering in a new era of efficiency and safety in woodworking.

Collaborative robots are not your typical industrial robots. They are a breed apart—lightweight, flexible, and designed to work alongside human operators. Unlike their massive and imposing industrial counterparts, cobots are streamlined and unobtrusive, taking up less space on the factory floor. Their primary role is to automate repetitive tasks, freeing up human workers to focus on more complex and creative aspects of their jobs.

The true revolution lies in the accessibility and versatility that cobots bring to the woodworking industry. In the past, automation was often associated with large-scale production lines and substantial investments. Cobots change the game by being easily deployable, even in smaller workshops and businesses. They cater to a wide range of applications, from sanding and painting to assembly and packaging.

Cobots have found a particularly welcoming home in the woodworking industry. Tasks that were once time-consuming and monotonous, such as sanding intricate wooden surfaces, are now efficiently handled by these robotic assistants. This is where the collaboration with different attachment heads comes into play. Take, for instance, Mirka’s orbital sander, a widely used tool in woodworking. Cobots, armed with the precise movements and control needed for a flawless finish, can be equipped with such attachments to carry out sanding tasks with remarkable precision.

The UR10e Arm by Universal Robots is a flagship example of the cobot revolution. Its slender build and six degrees of freedom make it adaptable to various woodworking tasks. Whether it’s sanding, painting, or assembly, the UR10e Arm can be programmed to perform with accuracy and speed. Its user-friendly interface ensures that even those with minimal programming experience can set up and operate the cobot effectively.

Another noteworthy contender is the Productive Robotics OB7. What sets this cobot apart is its “teach without programming” feature. This means that instead of relying on complex coding, operators can physically guide the OB7 through tasks, training it just like a new team member. This level of intuitiveness paves the way for a seamless integration of automation in woodworking processes.

So how exactly is the robotics-driven wood products industry transformation happening? Collaborative robots are democratizing automation, making it accessible to businesses of all sizes. Through the partnership of cobots and various attachment heads like Mirka’s orbital sanders, woodworking tasks are becoming not just automated but also refined to a level that only precision machinery can achieve. The symphony of human expertise and robotic precision is shaping a future where woodworking reaches new heights of quality and productivity.

Apply to Exhibit

Grow your business at the premier global woodworking trade show.

Show Hours & Location

International Woodworking Fair

Tuesday–Friday

August 6–9, 2024

Tuesday–Thursday

8:30 AM–5:00 PM*

Friday

8:30 AM–2:00 PM*

*Building A opens 7:30 AM Tue-Fri

Georgia World Congress Center

285 Andrew Young International Blvd

Atlanta, GA 30313