IWF Woodworking Today

Advancements in CNC Tooling: Empowering the Woodworking Community

August 9, 2023 | Dan Wellens

In the world of woodworking, Computer Numerical Control (CNC) technology has revolutionized the way intricate designs and precise cuts are achieved. Behind every successful CNC operation lies a vital element: tooling. As CNC technology evolves, so does the tooling used in the process. Let’s explore the recent advancements in CNC tooling, focusing on compression bits, V-bits, shaping and molding tools, and insert tooling. Additionally, we will discuss how companies like Vortex Tooling, Great Lakes Custom Tooling Manufacturing, and GDP Tooling contribute to the woodworking community’s growth and success.

Compression Bits:

Compression bits are specialized cutting tools designed to tackle both the top and bottom of the workpiece simultaneously. These bits have unique fluting, with the bottom portion being up-cut and the top portion being down-cut. This design prevents the top layer of the material from chipping while ensuring clean cuts through the bottom. Woodworkers and CNC operators commonly use compression bits for double-sided laminates, plywood, and other materials with vulnerable surfaces. The advancement in compression bit technology has significantly reduced material waste, minimized finishing work, and improved overall productivity.

V-Bits:

V-bits, also known as engraving bits, are invaluable tools for CNC machines used in woodworking. They have a sharp pointed tip in the shape of a V, which allows for precise engraving and detailed work on the material’s surface. With V-bits, woodworkers can create intricate designs, decorative patterns, and personalized engravings with ease. Developing sharper and more durable V-bits has opened up new creative possibilities, enabling woodworkers to add a touch of artistry and elegance to their projects.

Shaping and Molding Tools:

Shaping and molding tools are essential for producing complex contours and profiles on wooden surfaces. These tools enable woodworkers to recreate detailed moldings and artistic designs that were previously difficult to achieve manually. With the advancement in shaping and molding tool technology, CNC machines can now effortlessly replicate the most intricate patterns, resulting in consistent and flawless woodwork. This has saved artisans countless hours of manual labor and increased the accuracy of their craftsmanship.

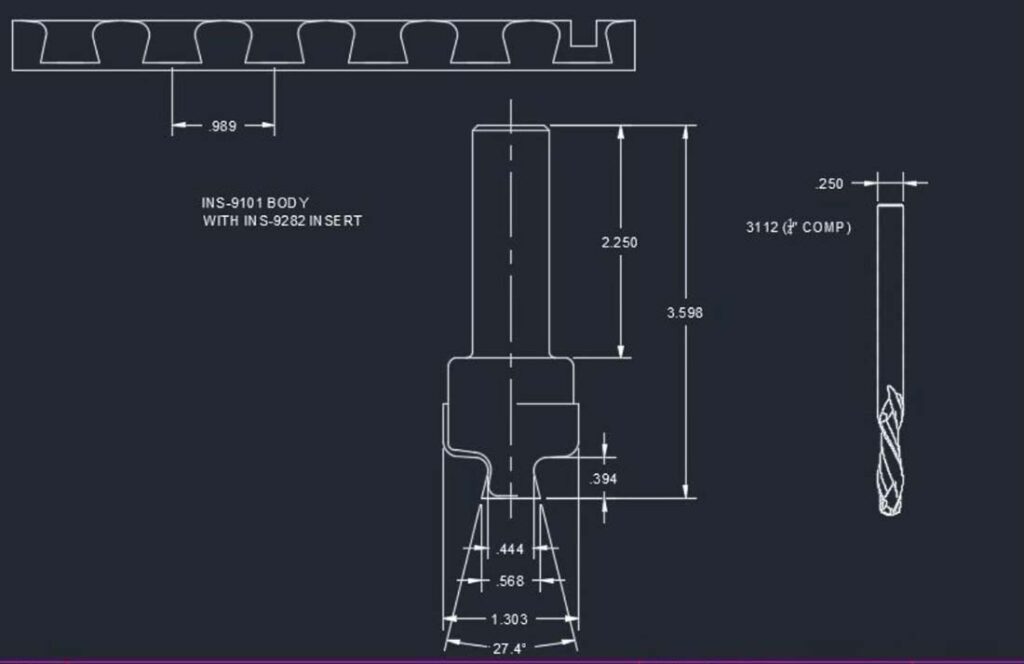

Insert Tooling:

Insert tooling is a modular system that uses replaceable cutting inserts rather than resharpening or replacing entire tools. This technology has revolutionized CNC operations, offering increased flexibility, reduced downtime, and cost savings. Insert tooling allows woodworkers to change the cutting edge quickly, enhancing the machine’s efficiency and versatility. It is now easier than ever to switch between different cutting profiles, reducing production time and boosting overall output.

Vortex Tooling, Great Lakes Custom Tooling Manufacturing, and GDP Tooling are prominent companies at the forefront of these CNC tooling advancements. They have been dedicated to understanding the specific needs of the woodworking community and developing innovative solutions. Their continuous research and development efforts have led to the creation of durable and efficient CNC tools. Compression bits, V-bits, shaping and molding tools, and insert tooling have become indispensable components of modern CNC operations. As technology evolves, we can expect even more exciting developments in CNC tooling, further empowering woodworkers to craft stunning creations precisely and easily. Be sure to view the complete catalogs from Vortex Tooling, Great Lakes Custom Tooling Manufacturing, and GDP Tooling to understand better what your CNC is capable of. Visit IWFAtlanta.com and utilize The IWF Product Finder to help research your tooling needs.

Apply to Exhibit

Grow your business at the premier global woodworking trade show.

Show Hours & Location

International Woodworking Fair

Tuesday–Friday

August 6–9, 2024

Tuesday–Thursday

8:30 AM–5:00 PM*

Friday

8:30 AM–2:00 PM*

*Building A opens 7:30 AM Tue-Fri

Georgia World Congress Center

285 Andrew Young International Blvd

Atlanta, GA 30313